Customized Bearing Solutions

- Customised rolling bearings

- Integrated complete bearing packages

- Application-optimized bearing solutions

More than 100 years have passed since the development and industrial distribution of rolling bearings. Rolling bearings are standardised, dimension plans are defined and interchangeability is guaranteed. From deep groove ball bearings to axial spherical roller bearings, there is a suitable rolling bearing for almost every application. In spite of this, industry-specific solutions have established themselves in many areas. Modern wheel bearings in the automotive industry are no longer standard bearings, but integrated and cost-optimized assemblies. Apart from large-scale production, such an approach is still very cautiously pursued, although the technical innovation possibilities and the improvement of the cost structure can be enormous.

The unique combination of quality, development competence and flexibility in the rolling bearing industry makes KRW the ideal partner when a standard solution is not the solution. Our experts in application technology and product development always understand bearings as an element of an entire machine. Thus, we are able to support you with our profound knowledge and to find the best solution for your bearing. As a medium-sized company, we are also flexible and therefore able to implement every adaptation and every new development quickly and easily.

Bearing Selection / dimensioning / calculation4 Reasons for Special Rolling Bearing Solutions

The reasons for choosing an adapted bearing solution are different; the possibilities are manifold. A complicated and expensive solution based on standard bearings is often used because it is assumed that a special solution is not available anyway or can only be implemented at high cost. In fact, there are many cases where the exact opposite is true. In practice, there are basically four main approaches whose development costs vary greatly.

1. Bearings in Special Dimensions

The most common and simplest reason for a customised bearing solution is to adjust the main dimensions of the bearing. After a machine repair, for example, it is necessary to rework the housing seats. In this case it is often the most straightforward and cost-effective solution to maintain the characteristics of the standard bearing and to manufacture it in the new, suitable main dimensions.

2. Modified Bearing Solutions

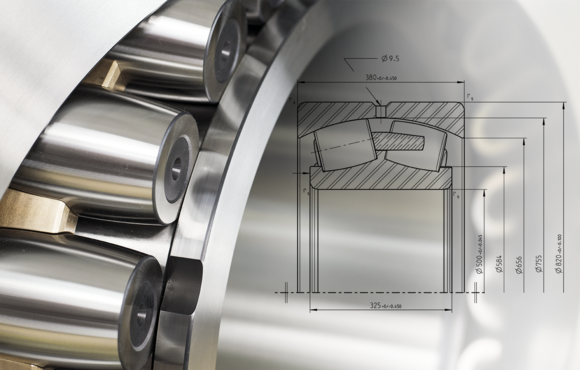

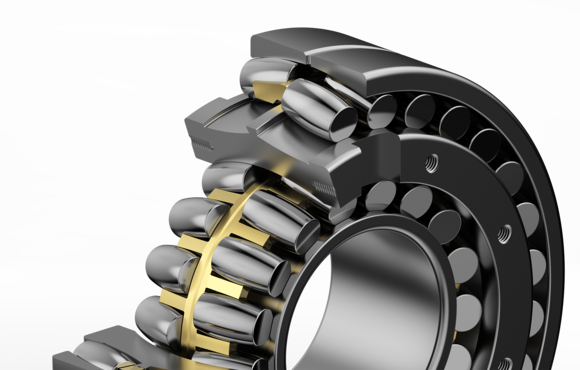

A continuing trend in the development of new machines is the desire for more performance. If you then reach the limits of individual components, you have to re-dimension them. However, building larger is inevitably associated with higher costs. If the problem concerns the bearing arrangement and the bearings used so far become too small, the cost increase is particularly high. In addition to the bearings themselves, the housing, the shaft and many conversion parts often become larger and more expensive. Downsizing, currently on everyone's lips, is the solution here. Depending on the bearing type and size, the internal geometry can be adapted, or a special cage can be used to optimise the number and dimensions of the rolling elements. An increase in load capacity of 10 %, for example, achieved in this way will approximately extend the service life by 40 %!

3. Integrated Bearing Solutions

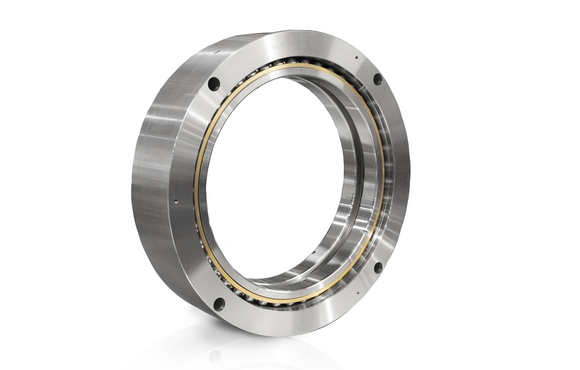

Often the designer does not dare to approach integrated solutions apart from large automotive series. It is assumed that in small series this is expensive or too complicated anyway; the idea of feasibility is simply missing. Rolling bearing rebuilds are often very precise. In addition, sensors, hydraulics and lubrication form important interfaces between bearings and attachments. Among other things, KRW is a development partner for companies in the machine tool industry and offers ready-to-install system solutions with significantly reduced assembly costs for the customer. Important conversion and attachment parts as well as measurement technology and sensor technology are already integrated in the bearing. Most of the time-consuming bearing assembly and especially the error-prone bearing adjustment are thus eliminated.

4. Customised Bearing Solutions

Bearings with the highest degree of individualization are particularly suitable for products manufactured in at least small series and whose best bearing solution in terms of design does not correspond to a standard solution. In exceptions, the requirements or the necessary dimensions of a bearing are so far from standard solutions that an individual solution can also be considered for one-off productions or is even the only sensible alternative. The challenges faced by our engineers are as varied as the problems faced by our customers. In cases of doubt, we simply redefine the limits of what is feasible.