Reconditioning of roller bearings

27.07.2018

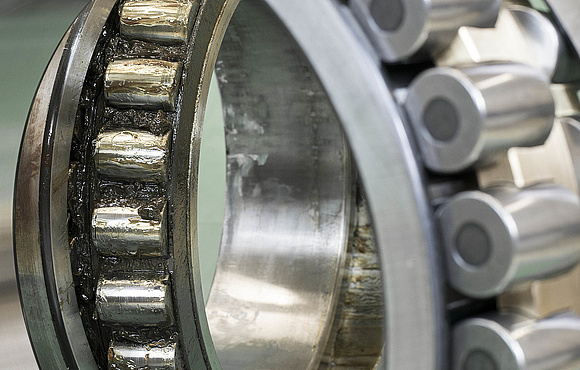

Large roller bearings, as they are used in machines for paper production, coal treatment and in heavy industry in general are high-value assets. Besides the interesting economic aspect, it becomes increasingly important that resources are preserved and used in a sustainable manner. In the event of wear and tear, it is often possible to repair a damaged bearing and return it to like-new performance instead of investing in a new one. Especially through preventive maintenance of large facilities, the replacement bearings can be examined regularly and cost-effectively. Hence, they often can be reconditioned and, without downtimes, be provided to the facility in a like-new quality.

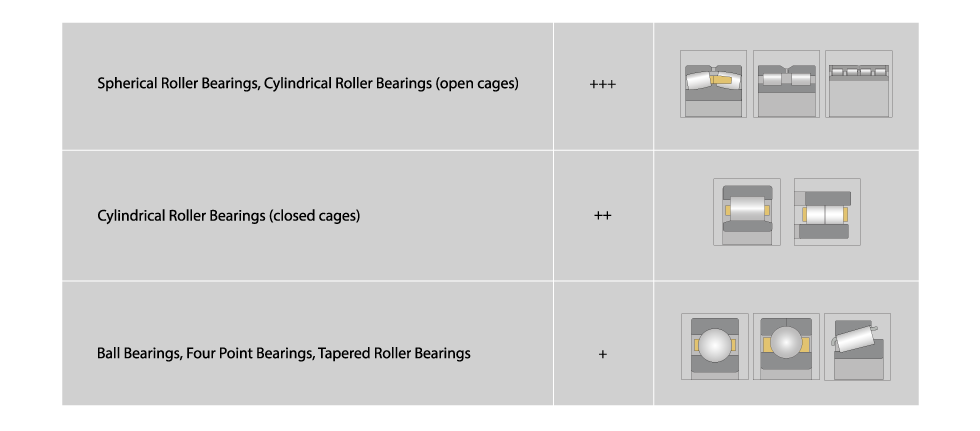

The suitability of different bearing types for reconditioning is simplified shown in Table 1. Dismountable bearings with an open cage design are generally easy to recondition. Closed designs as metal sheet cages or bolt cages can’t be opened non destructive and therefore only restricted reconditionable.

Overview of the reconditionable bearing types

The existing pattern of damage must not go beyond slight overrollings of foreign particles. Injured rings of bearings with starting pittings or cracks needs to be replaced. In such a case, the profitability of a reconditioning has to be verified on individual case. Subject to hidden material defects, reconditioned bearings have the same functionality and performance of new bearings. Compared to the costs of a new bearing, cost savings of up to 60%, depending on the type of bearing, could be reached. If it is possible to overhaul the outer and inner ring of the rolling bearing, also the delivery time will be reduced by up to 50%.

Further Information please see our portfolio of reconditioning of roller bearing.