Self-Aligning Cylindrical Roller Bearings

23.08.2018

Machine concepts with long distances between the bearing positions, such as tube dryers, plastic or paper calenders are, beside the huge shaft deflection also exposed to a process-induced high thermal expansion of several millimeters. In this case, the conventional bearing arrangement consisting of two spherical roller bearings on the fixed and floating bearing side, has its limits. A spherical roller bearing is reliably able to compensate angular deflections. The purpose of a floating bearing can only be realized by a sliding seat with the housing. This results in two, during the design process unnoticed problems:

1. The misalignment due to the strong shaft deflection as well as the axial thrust due to the shaft expansion superposing the movement of the bearings rolling elements. Thus, the kinematics of the spherical roller bearing are often more affected, as it was taken into account during the bearing conception. When analyzing bearing fatigue damages, not seldom, one sided damages or broken cages can be seen.

2. With increasing operating time, mechanical wear leads to deterioration of the housings fit. Applications with large differences between the process and ambient temperature tend to fretting corrosion, due to condensation. Both phenomena are significantly increasing the forces that are required for the floating bearing movement (drawer effect) or finally lead to a complete blockage. Therewith, a thermal change in length of the shaft can’t be compensated anymore. An axial overload of the bearings up to violent fractures of the bearing rings are the results.

Facing such problems, it is much better to realize the length compensation of the shaft inside the bearing. The adjustable KRW ACB-Bearings can realize this. Provided with a widened inner ring, the length compensation of the shaft happens inside the rotating bearing. Due to the very low friction between the rolling elements and the rings, the movement can happen unhindered. The spherical shaped outer ring provides the angle compensation by using plummer block housing of the SLG01-Series. Therewith the kinematics of the rolling elements and the load distribution inside the bearing will not be affected.

ACB bearings are double row, full complement cylindrical roller bearings. They are available as fixed and floating bearings with cylindrical or alternatively tapered bore. All versions are equipped with non-contact seals on both sides, thus ensuring reliable protection against contamination and leakage of the grease. The matching series SLG01 plummer block housings for KRW self-aligning ACB bearings consist of two parts and ensure an uncomplicated fitting and dismantling of the bearing.

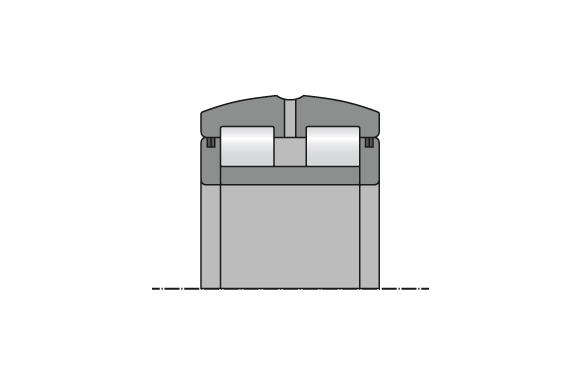

Fixed bearing ACB 05 (E)

Sealed, angular adjustable cylindrical roller bearing with tapered bore 1:12

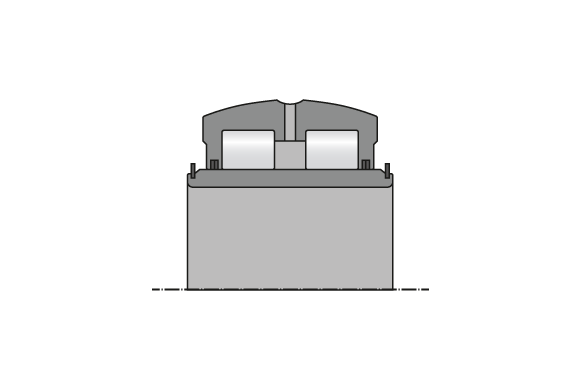

Floating bearing ACB 06 (E)

Sealed, angular adjustable cylindrical roller bearing with cylindrical bore (version for increased electric power)

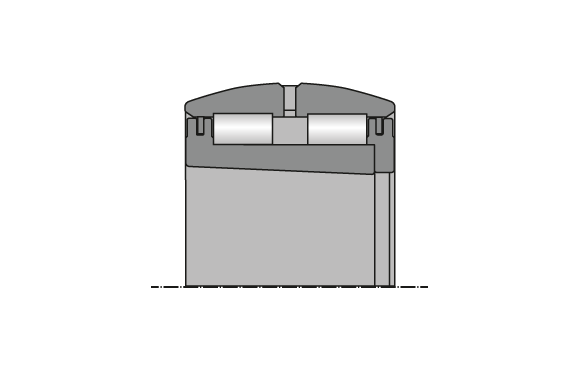

Fixed bearing ACB 07

Sealed, angular adjustable cylindrical roller bearing with tapered bore 1:12

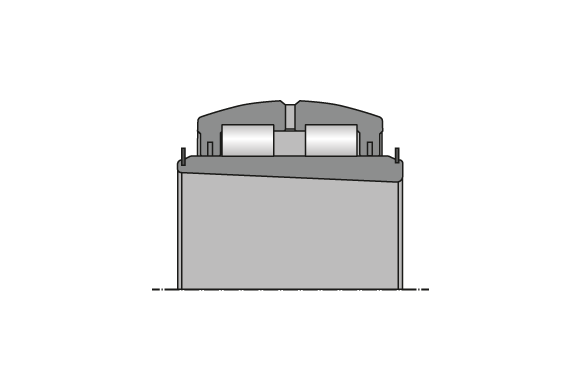

Floating bearing ACB 08

Sealed, angular adjustable cylindrical roller bearing with tapered bore 1:12

Further information can be found in our product brochure Self-Aligning Cylindrical Roller Bearings.