KRW - MPEA cages

22.01.2018

KRW revised the design of the outer ring guided brass window cage (MPA). This cage variant, that is used and established by many well-known bearing manufacturers, has reached the limits of its fatigue strength in the application of vibration loaded rail transmissions with a mileage of over 3 million kilometres. KRW developed the MPEA cage by using a design-accompanying FEM analysis and test series on different of test benches.

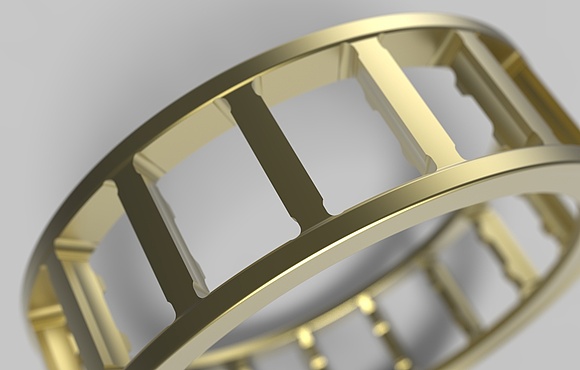

The new MPEA cage for cylindrical roller bearings

The innovative design combines the latest manufacturing technologies with our long lasting design experience. The stresses due to shock and vibration were reduced by up to 35% in critical areas. As a result, the fatigue strength is significantly improved. Mechanical safety against fatigue fracture has increased around 60%. Crack growth is significantly

reduced by geometric changes. In total, the operational reliability increased significantly for high mileages. Further improvements are the enhanced supply of lubricant in the roller-cage-contact as well as the more precise cage and rolling element guidance. This also increases the suitability for applications with very high speeds.

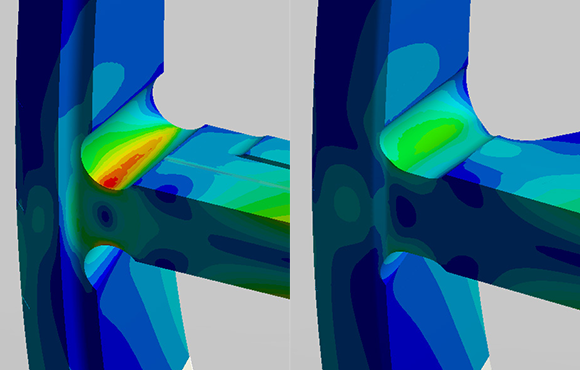

Comparison of the Von Mises stresses in the critical cross section for the same load on the MPA (left) and MPEA cage (right). The tension is depicted in different colors, increasing from blue to red.

For further information or an individual guidance, please do not hesitate to contact our application engineering team.