With hybrid bearings into the electromobility of tomorrow

26.02.2019

Rolling bearings in electric machines and drives are particularly susceptible to current leaks caused by potential differences within the machine. In these applications, current-insulated rolling bearings are used which have been coated with oxide ceramics on the outer or inner ring. Depending on the layer thickness, the bearings are insulated against DC voltages of 500 to 3,000 volts.

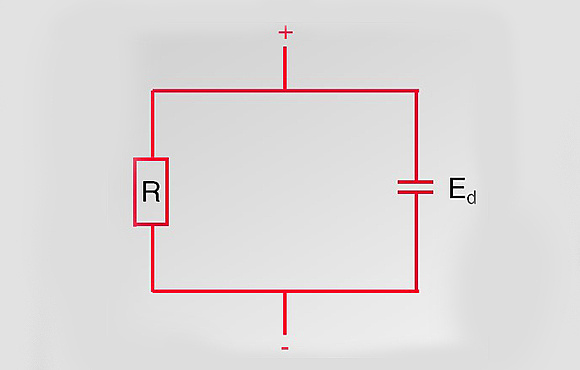

Electrotechnical diagram of the current insulation | Ed= dielectric strength of the dielectric; R= resistive resistance of the Coating; Xc= capacitive resistance

The current insulation layer acts like a parallel connection of a capacitor and an ohmic resistor in the DC current circuit. Figure 1 illustrates this relationship. Thus, the permissible insulation voltages result from the breakdown voltage of the capacitor.

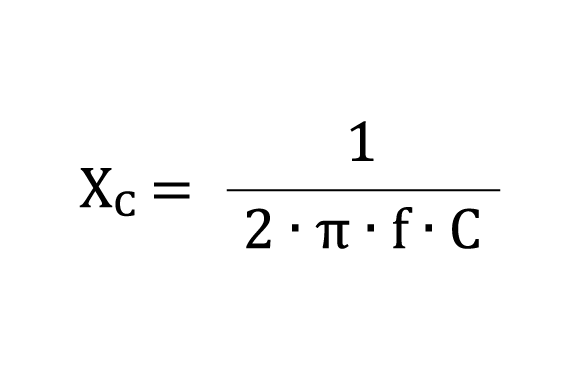

Xc = capacitive resistor; f = rotation frequency of the current; C = coating capacity

In contrast to the DC current circuit, the capacitive resistance in the AC circuit has a decisive influence on the current insulating characteristics of the coating. The formula for calculating the capacitive resistance shows that as the frequency increases, the resistance decreases.

Modern drive concepts in rail vehicle and machine construction rely on the easily controllable three-phase motors. These motors work with alternating current and are controlled by a frequency controller. Thus, for example, it is possible to align rotary tables in machine tools with an angular accuracy, to allow goods and passenger trains to travel across borders in different traction power systems without vehicle replacement, and to install compact and material-saving drives.

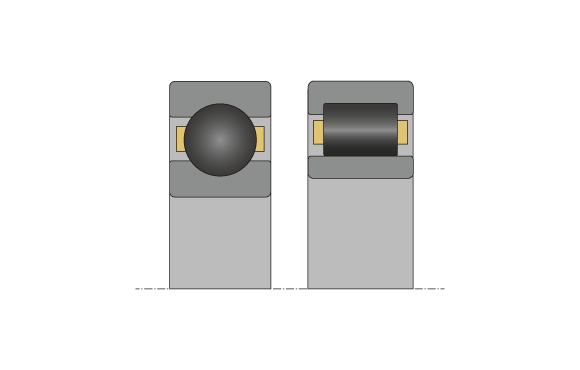

Hybrid ball bearings and hybrid cylindrical roller bearings (KRW suffix HC5)

Due to the increasing frequency control, high-frequency alternating currents are generated which, for technical reasons, cannot be diverted normally. In spite of the proven current insulation layer, it is physically possible for current to pass through and to damage the rolling bearing.

For this reason, hybrid bearings are used in these engines. These special bearings consist of ceramic rolling elements and conventional steel roller bearing rings. The rolling elements are predominantly cylindrical rollers and balls made of silicon nitride. Since this silicon nitride is characterized by a high electrical resistivity, hybrid bearings can be used wherever the classical coating fails due to capacitive currents.

In addition to a longer remaining term of lubrication failure, hybrid bearings have other positive properties: due to the lower density, hybrid bearings achieve a higher speed and a lower operating temperature. KRW offers hybrid bearings in standard and special dimensions.

For more information, please contact our sales team at salesnoSpam@krw.de