Railway and Transportation

Due to the rapid growth of the world population, environmentally friendly and resource-saving modes of transport are becoming increasingly important. Rail-bound transport plays a central role here. For decades, KRW has been a flexible and powerful supplier to the world's leading vehicle manufacturers, state railways, transmission and component manufacturers. Our many years of experience in the field of traction motor, transmission and wheelset bearings makes us an efficient partner not only for new developments. Rail vehicles are often operated far beyond the period of spare parts availability. Older components are often no longer available from series production. Flexible production, even in small series, also makes KRW an ideal partner in obsolescence management.

Applications

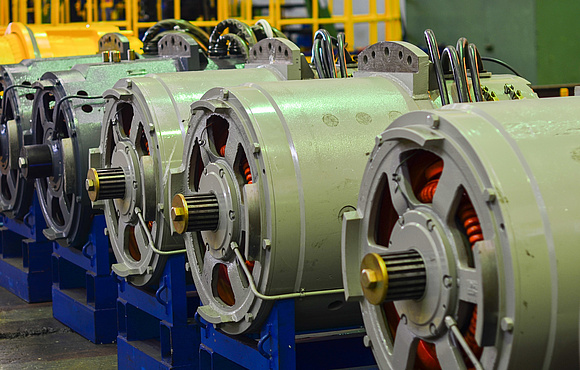

Traction Motors

Deep groove ball bearings or cylindrical roller bearings are predominantly used in traction motors. The classic motor bearing consists of a fixed-floating bearing arrangement. A distinction is made between the bearing positions on the output and fan side or in drive end and non-drive end.

Within a motor there is a potential difference between rotor and stator. To prevent potential equalization via the rolling bearings, KRW offers current-insulating coatings up to 3,000 V DC and hybrid bearings. The latter consist of rings made of rolling bearing steel paired with ceramic rolling elements and are available in deep groove ball bearing and cylindrical roller bearing designs. Especially for AC motors with a high-frequency control system, hybrid bearings are the safest method to prevent a damaging passage of current in the bearing.

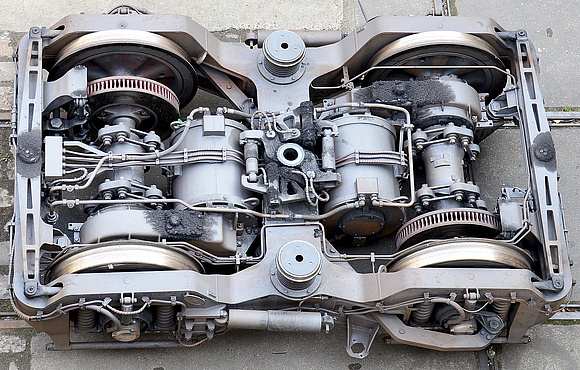

Hydrostatic Transmission, Hollow Shaft and Nose Suspended Gearboxes

KRW rolling bearings are represented in hydrostatic transmissions of older series through to modern nose suspended gearbox bearing and hollow shaft transmissions of multi-system locomotives. All bearings are optimised for the application as required. The modifications range from simple retaining or ring grooves for fixing, to special bearing designs and/or materials that are fully adapted to the conditions of the gear unit.

Due to the increased demands on the durability of transmissions, lightweight construction and energy-saving driving style, the loads on rolling bearings and their components have increased in recent years. KRW has met these requirements by developing the MPEA cage for cylindrical roller bearings. Its load-compatible design and optimum production technologies also meet the future requirements for rolling bearings in the field of railway transmissions and are used in bearings for well-known vehicle manufacturers and operators.

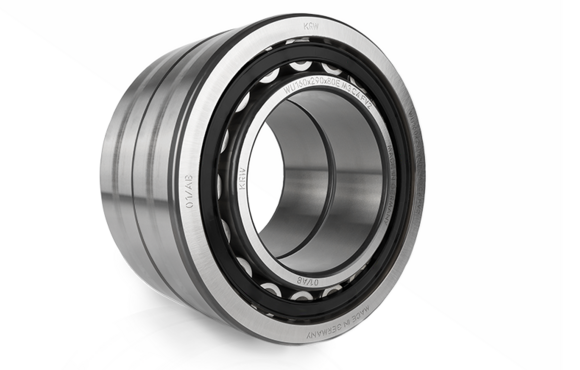

Wheelset Bearings

Wheelset bearings are the defined interface between wheelset and bogie and belong to the safety-relevant components. The most common types of wheelset bearings are cylindrical roller bearings and tapered roller bearings. Frequently used cylindrical roller bearings are standardised in DIN 5412-11. Both bearing types are manufactured at the factory to the highest quality class of EN 12080 (Class 1) and are fitted with glass fibre reinforced polyamide cages (suffix TVP) or brass cages. The spectrum ranges from the adaptation of the edge conditions and the current-insulating coating of the rings to the supply of sealed and greased axle box bearing units. The greases used conform to EN 12081. All wheelset bearings are released according to EN 12082 on customer request.

Services and Engineering

KRW fully supports its customers from the design of the bearing arrangement to advice on installation and lubrication. Ideally, the cooperation starts with the first draft. Based on the requirements from the subsequent machining process, KRW recommends the best bearing solution.

more