Hybrid Bearings

- Ceramic rolling elements

- High electrical resistance

- Suitable for very high speeds

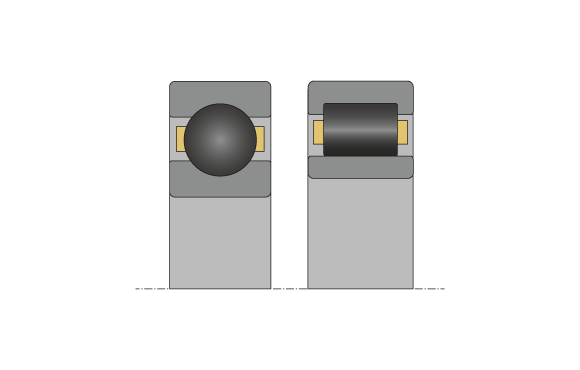

Rolling bearings in which ball races and rolling elements are made of different materials are called hybrid bearings. In most cases, the races of a hybrid bearing are made from roller bearing steel; in contrast, high-performance ceramics, e.g. silicon nitride Si3N4, are used for the rolling elements.

Application

Due to the particularly high dielectric strength of silicon nitride (Si3N4), hybrid bearings are mainly used in electric motors. Both modern drive concepts in rail vehicle construction and modern rotary tables in machine tool construction are increasingly equipped with hybrid bearings.

Silicon nitride has excellent properties that have a positive effect on the entire rolling bearing. KRW hybrid bearings have a significantly longer service life than rolling bearings made from standard steels, since they are both less sensitive to contamination in the contact area between the rolling element and the raceway and are positively influenced by the higher hardness of the high-performance ceramic Si3N4.

Due to the lower specific weight of the rolling elements, hybrid bearings are still particularly well suited for very high speeds. They are less sensitive to insufficient lubrication than standard bearings and therefore have better emergency running properties. Lower friction, less need for lubricant and operational reliability are further positive characteristics for choosing KRW hybrid bearings.

KRW supplies hybrid bearings in the designs of deep groove ball bearings and cylindrical roller bearings. Special dimensions are also possible on request.

Special Suffixes

| HC.. | Hybrid bearing, bearing parts are made of silicon nitride Si3N4, suffix followed by a number indicates the affected parts group |