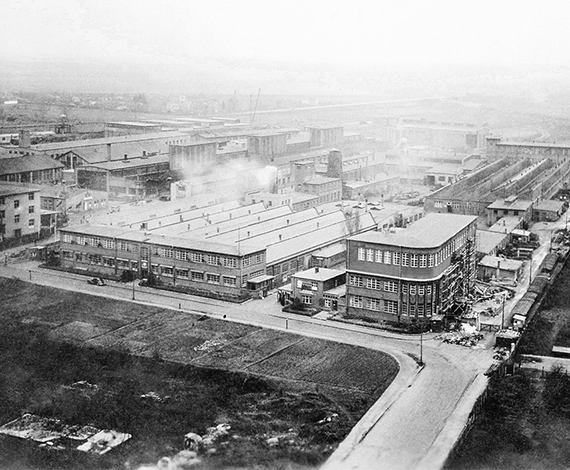

Production at KRW

From Engineering to the Finished Product – Rolling Bearings from Leipzig.

Since 1934, rolling bearings have been developed and manufactured in our traditional factory in the west of Leipzig. Over 260 well-trained and highly motivated employees produce KRW rolling bearings – Made in Germany – on an area of 36,000 m². As a medium-sized rolling bearing manufacturer, we are proud of the high vertical range of manufacture, which enables us to control every step of the manufacturing process of a rolling bearing. This ensures that all products in our broad portfolio, from 1 kg deep groove ball bearings for electric motors to 3 ton thrust roller bearings for power plants, meet our stringent quality requirements.

KRW stands for flexibility and customer orientation – also and especially in production. We rely on flexible manufacturing units and state-of-the-art technologies in all areas of production. This allows us and our products to remain flexible for our customers.

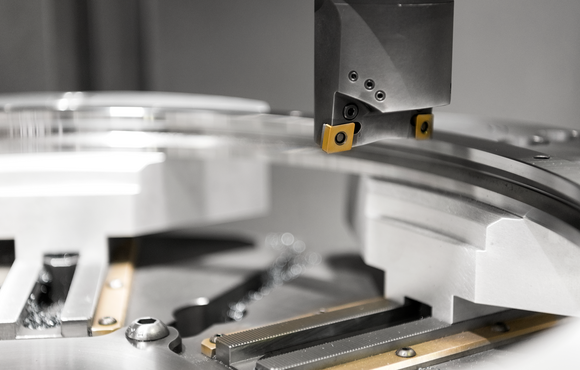

Soft Machining

The production of each component of a rolling bearing starts with soft machining. Here, the rolling bearing rings and components to be produced are machined near-net-shape; bores, threads, lubrication channels and more complex shape elements are produced.

Heat Treatment

In the in-house hardening shop, the material properties that are so important for the longevity of the rolling bearings are adjusted. Thus, the right hardening technology is used for every material, whether martensitic or bainitic hardening as a standard or various case hardening processes for special applications. The hardening shop is accompanied and monitored by our in-house metallography laboratory, which ensures that the high demands placed on our products are always met correctly.

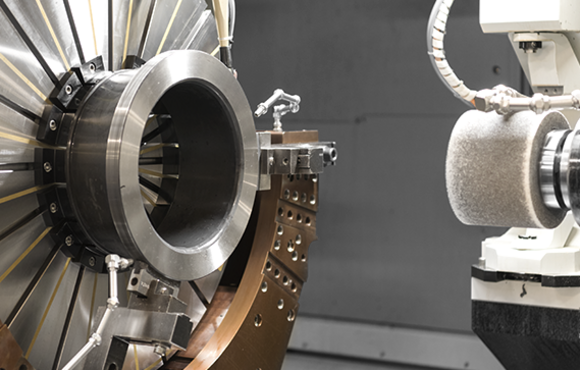

Hard Machining

Hard machining is the heart of production. Latest technologies paired with the experience of engineers and skilled workers determine the accuracy and running characteristics of KRW rolling bearings. The precision of our products always results from the interaction of all production steps, but accuracy down to the micrometer is only achieved through this.

Assembling

During assembly, the finished individual parts are completed to form a rolling bearing. This is where the final inspection, special functional tests and the preservation and packaging of KRW products take place.

As a medium-sized rolling bearing manufacturer, we are proud of the high level of vertical integration that enables us to control every step in the production of a rolling bearing.