Motors, Generators and Turbines

Electrical machines and drives require special rolling bearings which are adapted to the requirements of these installations. In particular, the breakdown of electric current represents an increasing problem with the use of drives controlled by frequency converter.

Turbines and compressors are located almost exclusively in branched installations, such as thermal energy turbines, or in geographically inaccessible areas, such as gas compressors in pipelines. Repair and downtime costs for such systems are enormous and rolling bearings made of conventional rolling bearing steel often do not achieve the required service life under these extreme operating conditions.

Applications

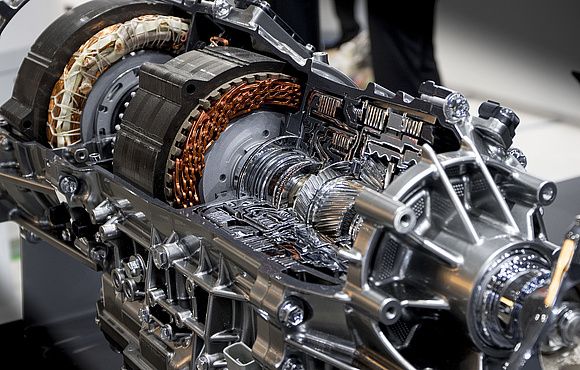

Electrical Machines and Drives

In addition to their long service life, high load capacity and suitability for variable speeds, the rolling bearings for electric drives must also have a high degree of precision and optimal internal geometry. KRW supplies a wide range of rolling bearings that meet these requirements.

KRW offers current-insulating coatings for inner and outer rings up to 3,000 V DC for effective protection against the passage of current, which causes massive damage to the raceway and the rolling elements. With AC motors controlled by frequency inverters, current-insulating layers are no longer sufficiently effective at high frequencies, which is why KRW also offers so-called hybrid bearings. These are equipped with ceramic rolling elements for current insulation. Further advantages of these bearings are the increase of the achievable speed and their reduced grease consumption.

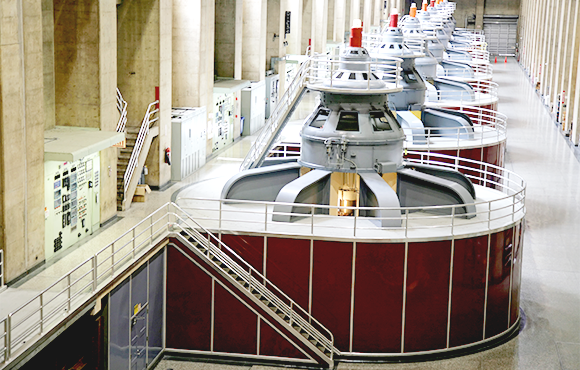

Turbines and Compressors

The downtime costs of a power generating turbine or a gas compressor due to bearing damage are much higher than those of a new bearing purchase. For example, operators of such installations require that the service life of the rolling bearings used must at least correspond to the service life of the turbine or compressor. The rolling bearings usually run in aggressive media, e.g. acids or bases, and are installed very deep inside the systems. Rolling bearings made of hardenable, stainless steel offer reliable protection against chemical influences and achieve long service lives even under high loads and difficult lubrication conditions.

Services and Engineering

KRW provides its customers with full support from the design of the bearing arrangement to advice on installation and lubrication. Ideally, the cooperation starts with the first design. Based on the requirements from the subsequent application, KRW recommends the best bearing solution. If this is not yet available, we will develop it from scratch.

More