Cylindrical Roller Thrust Bearings

single direction

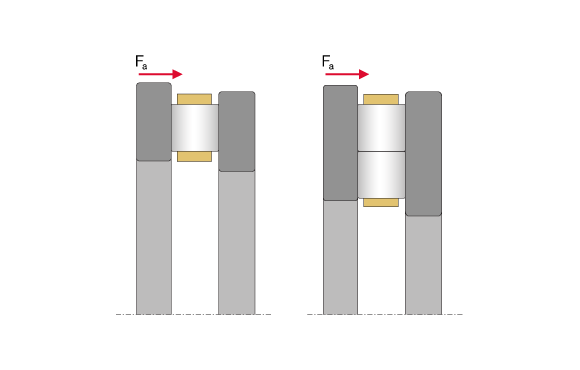

- Absorption of axial forces from one direction

- No absorption of radial forces

- Available in highest precision for machine tools

Single direction cylindrical roller thrust bearings consist of one shaft washer, one housing washer and an axial roller cage assembly. They can absorb high axial forces from a single direction, but no radial forces. Single direction cylindrical roller thrust bearings are non-latching, so the roller cage assembly and the bearing rings can be assembled separately.

Dimensions and Tolerances

KRW supplies spherical roller thrust bearings with normal tolerance (PN) in accordance with DIN 620-3 (Tolerances for rolling bearings) and ISO 199 (Thrust bearings - Geometrical product specification (GPS) and tolerance values). All other deviating or special tolerances must be specified with the order.

Bearing Design

Single direction cylindrical roller thrust bearings are dismountable and non-latching bearings. They can absorb high axial forces from a single direction, but no radial forces.

As an alternative for the externally centred housing washer or internally centred shaft washer, a race washer can be used when there is no need for an exact centring.

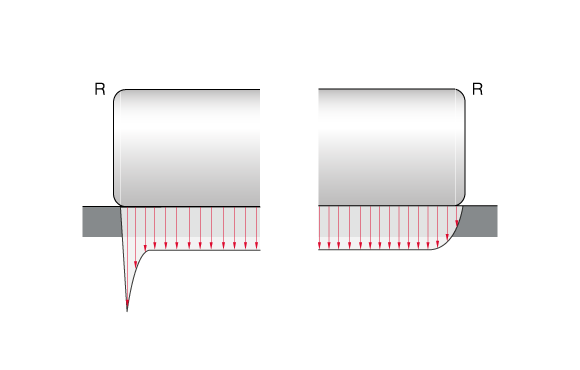

Due to the logarithmic profiling of the cylindrical rollers, damaging edge tension and resulting premature failure are avoided.

Bearing Clearance

The bearing clearance for single direction cylindrical roller thrust bearings is adjusted only after installation according to operating conditions. The temperature-dependent length variation of the operating components must be considered.

Cage

By default, KRW cylindrical roller thrust bearings are equipped with a solid brass cage (suffix: M). Other cage designs are available on request or chosen for specific applications and labelled accordingly on the bearing.

Suffixes

Compensation of Angular Misalignments

Single direction cylindrical roller thrust bearings are not suitable for compensation of misalignments. Misalignments cause edge stresses between rolling elements and raceways and produce additional stresses in the bearing which reduce its operating life.

Speed

KRW distinguishes between kinematic limiting speed nG and thermal reference speed nth. The kinematic limiting speed is a practical mechanical limit value and is based on the mechanical fatigue strength of the rolling bearing as a function of its installation situation and lubrication. The limit speed must not be exceeded even under optimum operating conditions without prior consultation with KRW.

The thermal reference speed represents the equilibrium between the heat generated in the bearing by friction and the heat flow dissipated. It is standardised in DIN ISO 15312 (Rolling bearings - Thermal reference speed).

Admissible Operating Temperatures

The admissible operating temperature of a bearing is limited by cage material, dimensional stability of the bearing components (ball race and rolling elements), as well as lubrication. By default, KRW bearings are stabilised up to 200°C (S1). KRW provides roller bearings for higher operating temperatures on request.

Dimensioning

For dynamically loaded bearings

The service life formula according to ISO 281 L10 = (C/P)p for dynamically loaded bearings requires an equivalent load (P) from constant direction and size. To calculate P, calculation factors and the ratio of axial and radial load are required.

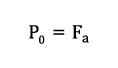

Equivalent Dynamic Bearing Load Pa

The equivalent dynamic bearing load can be determined using the following formula:

| Pa | equivalent dynamic load | [kN] |

| Fa | dynamic axial force | [kN] |

For statically loaded bearings

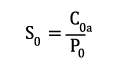

Dynamic dimensioning loses its validity for bearings rotating at very low speeds (n x dm ≤ 4000 mm/min). The static load safety factor S0 is calculated as follows:

| S0 | static load safety factor | [-] |

| C0a | static load rating (from bearing chart) | [kN] |

| P0 | equivalent static bearing load | [kN] |

| n | speed | [min-1] |

| dm | mean bearing diameter [dm = (D+d)/2] | [mm] |

Static load capacity

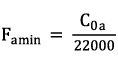

Minimum Axial Load

A minimum load is required for the reliable operation of a rolling bearing. If the minimum load is not reached, slippage may occur. This produces surface damage which leads to premature bearing failure. Cylindrical roller thrust bearings are protected against slippage exclusively through a minimum axial load. The calculation for the minimum axial load for cylindrical roller thrust bearings is shown in the following formula: