Paper and Plastic Processing

From pulp products to newspapers and magazines to packaging of all kinds. Paper and plastics have become an integral part of modern society. In 2018 alone, more than 400 million tons of paper and over 350 million tons of plastics for packaging purposes were produced worldwide. KRW bearings are found both in paper machines and in high precision calenders in plastics processing.

Paper Processing

Paper processing plants, which are divided into several main areas, place high demands on the machine parts and the installed bearings. Rolling bearings with optimum performance enable a long service life of the system components.

Wet Section

Suction, wire and press rolls are integrated in the wet areas to dewater the paper webs. The bearings must withstand high contact pressures and thermal effects. The high load bearing series 232 and 223 are ideally suited for these loads. KRW spherical roller bearings for this area are manufactured for most systems with internal clearance C3 and increased running accuracy to improve the surface quality of the paper web. Alternatively, self-aligning bearings of the ACB series can be used as floating bearings or as floating and fixed bearings. The spherically shaped outer ring allows shaft deflection to be accommodated, with thermal expansion being accommodated in the bearing without constraint.

Dryer Section

Large heating cylinders are used to further reduce the water content in the paper webs, which represents an additional thermal load for bearings. Spherical roller bearings of series 230 / 231 with an increased clearance C4 and a specially heat-treated inner ring are usually used for this purpose. In the following calender these series are also mainly used for bearings. This is where the final surface quality of the product is created and thus represents a very important step in paper production. A distinction is made between a non-heated and a heated calender. In addition to the high contact pressure, a heated calender has a further thermal load. Here, as in wet areas, self-aligning cylindrical roller bearings from the ACB series can also be used as floating bearings or as floating and fixed bearings. The spherically shaped outer ring allows shaft deflection to be accommodated, with thermal expansion being accommodated in the bearing without constraint.

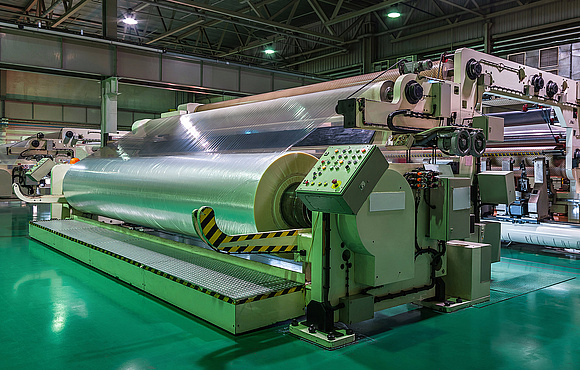

Plastics Processing

In plastics processing, bearing characteristics such as load carrying capacity, thermal stability and above all accuracy are decisive for the design and operation of plastics processing machines.

Calender for the production of plastic films are highly stressed machines, which must have a high level of consistency and reliability over the entire service life. The bearings of the calender rolls, which weigh several tons, play a central role here. The forces acting on the bearings are a combination of deadweight, splitting, bending and thermal expansion forces. The thinner the calendered product, the higher are the requirements for the conversion parts and the bearings. The roundness and the concentricity of the roll bearings are responsible for the constancy of the nip over the entire length of the calender rolls during the entire smoothing process and thus directly for the quality of the end product. KRW bearings are used in this area mainly because of their high accuracy, coupled with the load carrying capacity of high purity steel and special heat treatment. Each of the bearing types currently used, cylindrical roller, tapered roller or spherical roller bearings, achieve concentricity accuracies of a few micrometres.

- Spherical Roller Bearings

- Spherical Roller Thrust Bearings

- Tapered Roller Bearings

- Tapered Roller Thrust Bearings

- Self-Aligning Cylindrical Roller Bearings (ACB series)

A special development from this area are KRW precision spherical roller bearings, which ensure the quality of the product through a constant nip between the calender rolls. For this purpose, the bearing tolerances are reduced to such an extent that a total concentricity of 3 micrometres is also possible in a spherical roller bearing. This variant also allows various sealing concepts, which further improve the reliability of the entire system.

Services and Engineering

KRW offers a comprehensive engineering service. Customer projects are also developed to define the optimal operating conditions for the bearings. We accompany you from the first idea to the finished product.

more