Spherical Roller Bearing

metric

- Compensation of angular misalignments

- Absorption of high radial and axial forces from both directions

- Suitable for medium speeds

Spherical roller bearings are double row, angularly adjustable bearings which can compensate angular misalignments due to the spherical outline of the outer ring raceway and the barrel-shaped rolling elements. They absorb very high radial as well as axial forces, but they are not suitable for high speed needs. Spherical roller bearings cannot be disassembled and are suitable for use with heavy shaft deflections and angular misalignments between bearing positions.

Bearing Design

Spherical roller bearings are two row, self-latching radial bearings that cannot be disassembled. They can absorb high radial forces as well as axial forces from both directions. Spherical roller bearings are available with cylindrical or tapered bore and are manufactured in three different designs depending on application needs.

The standard design by KRW (suffix: EA) is optimised for load carrying capacity. The double-chamber brass cage rests on the rolling elements that are guided by two outer flanges on the inner ring. Bearings with the suffix A have an additional solid centre flange. This design usually has a lower load rating, but it is significantly more suitable for applications with changing axial loads, high speeds or shock loads due to the additional guiding of rolling elements and cage.

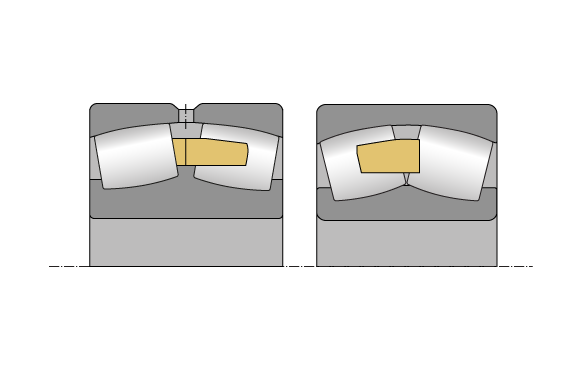

Spherical roller bearing Type A (left), spherical roller bearing Type EA (right)

Type | Description |

A | inner ring with centre flange and outer flanges; divided brass chamber cage |

EA | inner ring with outer flanges; brass double-chamber cage |

Bearing Clearance

KRW supplies spherical roller bearings in normal clearance (CN) in accordance with DIN 620-4 (Rolling bearing tolerances) and ISO 5753-1 (Rolling bearings - Internal clearance), but they are also available in all clearance classes with restricted clearance or special clearance.

| ||||||||

Cage

By default, spherical roller bearings by KRW are equipped with a rolling element riding solid brass window-type cage (suffix: M). Other cage designs are available on request or chosen for specific applications and labelled accordingly on the bearing.

Special Suffixes

| A | Modified internal design, inner ring with two lateral retaining ribs and one central rib |

| EA | Modified internal design, inner ring with two lateral retaining ribs |

Compensation of Angular Misalignments

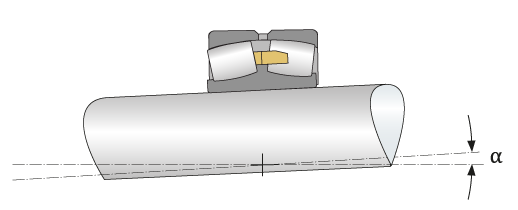

Spherical roller bearings are suitable for compensation of misalignments between inner and outer bearing rings due to shaft deflections, angular errors and housing deformation. The maximal admissible angular misalignment with static and circulating inner ring is:

| Spherical roller bearing series | max. angular misalignment |

| 213, 222, 230, 239, 240, 241 | 1,5° |

| 223, 231, 232, 233 | 2° |

Deviating angles are available on request or custom-designed.

Speed

KRW distinguishes between kinematic limiting speed nG and thermal reference speed nth. The kinematic limiting speed is a practical mechanical limit value and is based on the mechanical fatigue strength of the rolling bearing as a function of its installation situation and lubrication. The limit speed must not be exceeded even under optimum operating conditions without prior consultation with KRW.

The thermal reference speed represents the equilibrium between the heat generated in the bearing by friction and the heat flow dissipated. It is standardised in DIN ISO 15312 (Rolling bearings - Thermal reference speed).

Admissible Operating Temperatures

The admissible operating temperature of a bearing is limited by cage material, dimensional stability of the bearing components (ball race and rolling elements), as well as lubrication. By default, KRW bearings are stabilised up to 200°C (S1). KRW provides roller bearings for higher operating temperatures on request.

Dimensioning

For dynamically loaded bearings

The service life formula according to ISO 281 L10 = (C/P)p for dynamically loaded bearings requires an equivalent load (P) from constant direction and size. To calculate P, calculation factors and the ratio of axial and radial load are required.

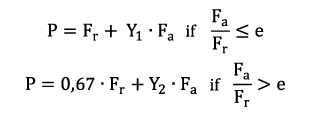

Equivalent Dynamic Bearing Load P

The equivalent bearing service life for the single row spherical roller bearings depends on the ratio Fa/Fr . The equivalent dynamic bearing load can be determined using the following formula:

| P | equivalent dynamic load | [kN] |

| Fr | dynamic radial force | [kN] |

| Fa | dynamic axial force | [kN] |

| e | calculation factor (see bearing chart) | [-] |

| Y1 | calculation factor (see bearing chart) | [-] |

| Y2 | calculation factor (see bearing chart) | [-] |

For statically loaded bearings

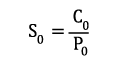

Dynamic dimensioning loses its validity for bearings rotating at very low speeds (n x dm ≤ 4000 mm/min). The static load safety factor S0 is calculated as follows:

| S0 | static load safety factor | [-] |

| C0 | static load rating (from bearing chart) | [kN] |

| P0 | equivalent static bearing load | [kN] |

| n | speed | [min-1] |

| dm | mean bearing diameter [dm = (D+d)/2] | [mm] |

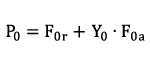

Static load capacity

| F0r | max. radial static load | [kN] |

| F0a | max. axial static load | [kN] |

| Y0 | calculation factor (see bearing chart) | [-] |

Minimum Radial Load

A minimum load is required for the reliable operation of a rolling bearing. If the minimum load is not reached, slippage may occur. The minimum radial load for spherical roller bearings is roughly assumed to be 1.25% of the static load rating C0 of the bearing. If the value falls below this value, please consult KRW Application Technology.