Reconditioning

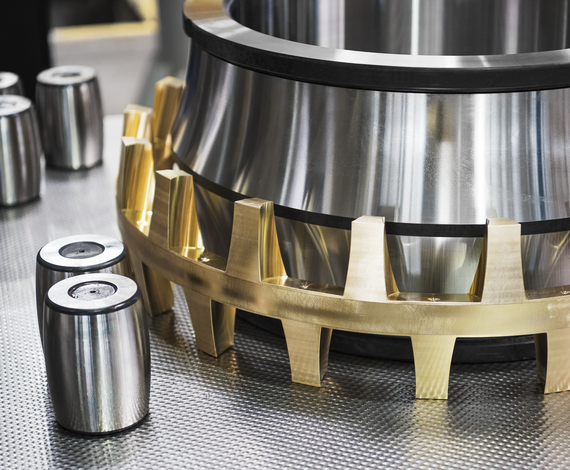

Large roller bearings, as they are used in machines for paper production, coal treatment and in heavy industry in general are high-value assets. Besides the interesting economic aspect, it becomes increasingly important that resources are preserved and used in a sustainable manner. In the event of wear and tear it is often possible to repair a damaged bearing and return it to like-new performance instead of investing in a new one. Especially through preventive maintenance of large facilities the replacement bearings can be examined regularly and cost-effectively. Hence, they often can be reconditioned and, without downtimes, be provided to the facility in a like-new quality.

Which bearing types are eligible for a reconditioning process?

- Expensive and material-intensive bearings

- Bearings with only little to medium damages

- Bearings with short wear intervals

- Bearings that were replaced during previous maintenance

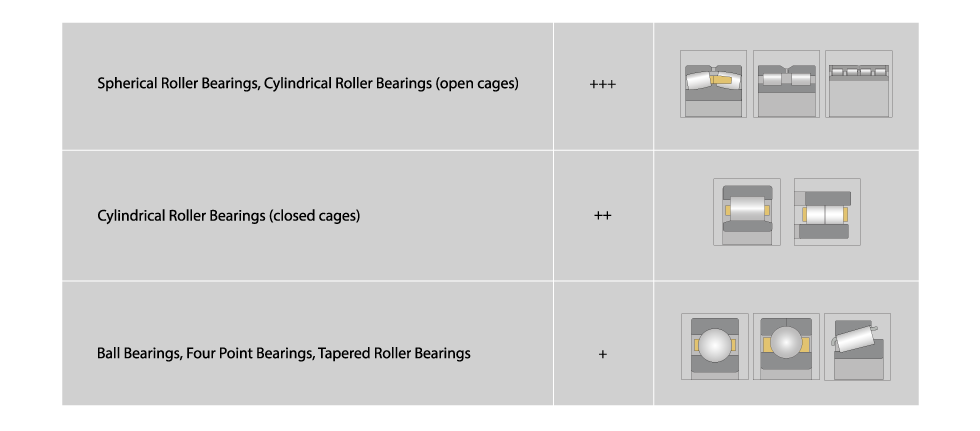

The reconditioning of demountable bearings with an open cage design is generally economically reasonable. Closed sheet metal cages or bolt cages can only be opened destructively and can therefore only be prepared to a limited extent.

The existing pattern of damage must not go beyond imprints and cyclings of foreign particles. In the case of bearings with beginning pits or cracks, individual rings must be replaced, which means that the cost-effectiveness of reconditioning must be checked in individual cases. Reconditioned rolling bearings, subject to hidden material defects, have the full functionality and performance of new rolling bearings.

1. Cleaning and Dismounting

The bearing is cleaned from dirt and lubricants and washed afterwards.

2. Diagnosis

Before reconditioning, the bearing is examined and it is determined, whether or not a reconditioning process is feasible. After a detailed examination and the decision for a recon-ditioning process it is assessed, which components of the bearing have to be replaced or repaired. Finally, an investigation report is compiled.

3. Reconditioning

Depending on the bearing condition three levels of remanu-facturing are distinguished. The greater the wear, the higher the processing effort.

Reconditioning level I: Cleaning and polishing of all components

Reconditioning level II: Grinding of at least one raceway as well as application of new oversize rollers and polishing of the remaining elements

Reconditioning level III: Grinding of at least one raceway as well as application of new allowance rolling elements; exchange of single elements and polishing of the remaining elements

4. Check/Mounting

All components are manufactured and examined in accordance with our strict quality guidelines. After completion of the bearing a final inspection follows. All examination results are provided in a detailed report upon request.

Are you interested in further information about the application possibilities of reconditioning? Write us or give us a call.

Contact