Support Roller Bearings

- Most precise sorting in sets

- Case-hardened rings for highest loads

- Open or sealed designs

Support roller bearings are cylindrical roller bearings and can support very high radial or combined forces, depending on the design. The surface quality of the outer surface of the outer ring, the running accuracy and the height tolerance are decisive for the quality of a rolled sheet.

Cluster mills are cold rolling mills in which strips of stainless steel and non-ferrous metals are formed. To ensure that the deflection of the work roll is very low, it is supported by intermediate rolls and support axles. KRW support roller bearings are used on the support axles. Usually several support roller bearings are located next to each other on the support axle separated by support saddles.

The following specific properties are defined for support rollers to ensure the surface quality and flatness of the rolled products:

running precision better than P4

additional restricted tolerances

sorting into three to seven height groups, depending on the tolerance, in 3 µm to 5 µm steps

the profiling of the rolling elements and raceways enables the bearings to be used under particularly high loads

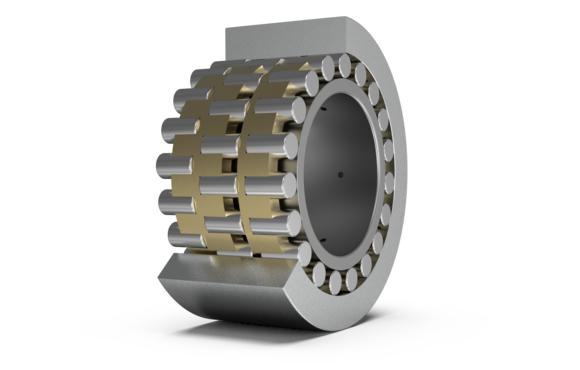

Design A: three-row bearing

-

ribless outer ring

-

first and second row in double comb cage made of brass

-

third row in a single comb cage

-

rib rings on the inner ring guide the rollers axially

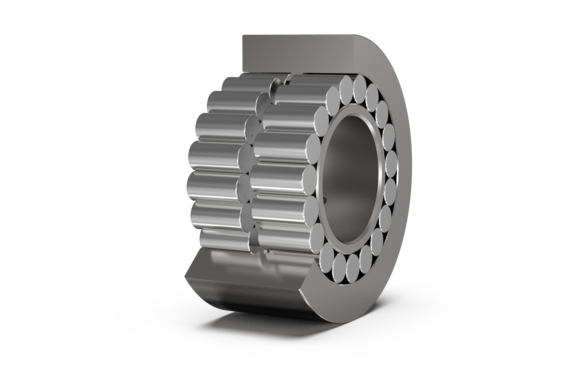

Design B: double-row bearings

-

outer ring with two ribs

-

rollers are guided in a double comb cage

-

sealing of the bearings is possible

Design C: double-row full complement bearing

-

one central rib each on the outer ring and inner ring