Industrial and Large Gearboxes

The main task of gearboxes is the transmission and transformation of motion, energy and/or forces. In recent decades, their development has been strongly promoted, and the throughput, particularly for industrial and large gearboxes, has increased significantly. The higher loads require high demands on all gear components. In particular, the rolling bearings are faced new challenges with limited installation space, thin-walled housing constructions and fluctuating load conditions.

Applications

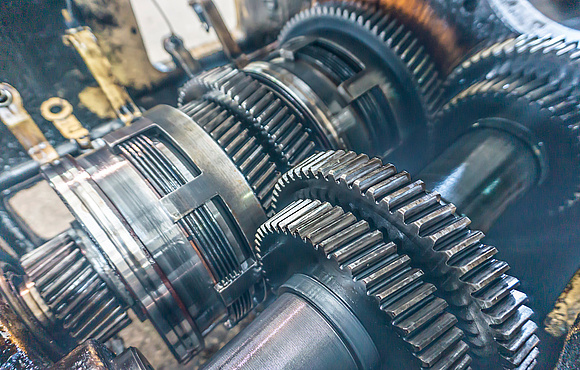

Spur Gear Unit

Spur gear units are the simplest and the most frequently used types of gear units. They are used as manual gearbox in motor vehicles up to heavy rail vehicles or in ship drives. Depending on the throughput, there are spur, helical and double-helical gears. Each of these designs require special demands on the bearings. The straight-toothed variant is characterised by high radial forces and vibrations, while the helical-toothed variant contains an additional axial force component that has to be absorbed by the bearing. Typical bearings are non-locating bearings, fixed bearings with component separation or floating bearings.

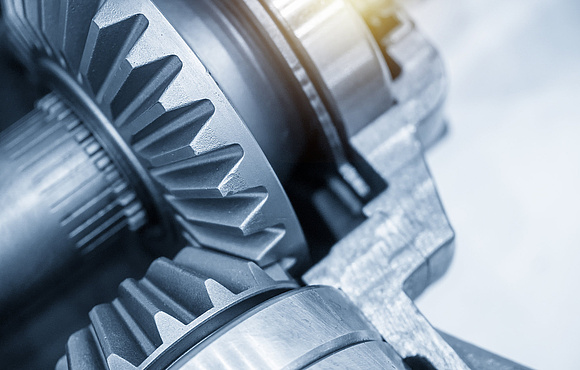

Bevel Gear Unit

The bevel gear unit is characterised by its compactness and high-power throughput, which means that it requires additional demands on the bearings. In addition to the radial load components, there are also high axial forces which are optimally absorbed by using high-performance tapered roller bearings.

Planetary Gear Unit

Planetary gearboxes, also called epicyclic gearboxes, are a very compact type of gearbox and achieve a very high gear ratio. For this reason, the design is particularly interesting for modern wind turbines, in which it is used in combination with additional spur gear stages. The flexibility of the gearbox design enables a change of input and output between the individual components - ring gear, sun gear and planet - and thus varying requirements on the bearings. In particular, the multi-row planetary bearings, mounted directly in the planetary gear, require very high accuracy of a few micrometres between the individual raceways.

Services and Engineering

KRW is a high-performance and fast development partner of many gearbox manufacturers and has already proven its development expertise in the simultaneous engineering of wind turbine gearboxes. Taking into account the internal bearing geometry, component outline, temperatures, shaft deflection and even chained housing stiffness, we are able to not only develop the necessary bearings in a very short time, but also to certify them according to current standards.

more