Load increase by the use of tapered roller bearings

28.07.2019

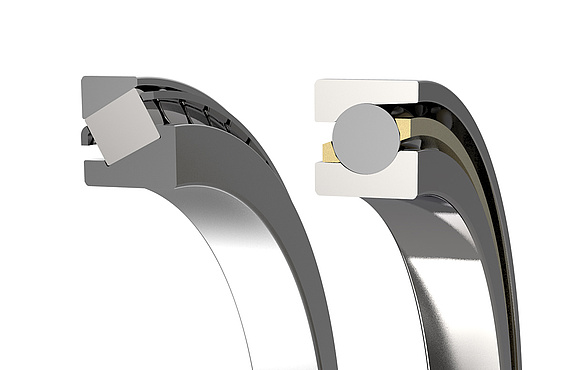

In the drives of large machines for ore processing rolling bearings are often subject to strong vibrations, hitting loads and high loads. There is just a very limited space for the gearbox; this is why the rolling bearings have to have a very narrow design. In the following example angular contact ball bearings were originally used as a moment bearing of the planetary stage.

Given the very high base loads and superimposed impacts, the surface pressure in the rolling contact increases sharply and inevitably leads to premature failure of the bearings. In order to avoid a complete redesign of the machine, a KRW searched for a bearing with improved mechanical properties with a constant installation space. Our engineering team developed tapered roller bearings in a very narrow version, which can be exchanged 1: 1 with the existing angular contact ball bearings.

With application-specific internal geometry, a maximum load rating and an optimal pressure angle for the occurring loads are achieved. In contrast to angular contact ball bearings, tapered roller bearings also have higher rigidity. In the axial direction, the stiffness could be doubled, even tripled in the radial direction.

By doubling the load rating, the theoretical life of the bearings improves four times over comparable load. In addition to a corresponding extension of the maintenance intervals, a more continuous working of the gear is thus made possible and thus also extends the life of other components of the system.

For further information please contact our sales team or our application engineering team.